4 of 4 Product variants

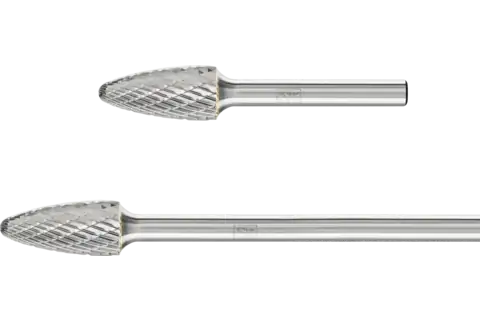

| Item number / EAN | Cut | Dia. external | Dia. shank | Length, cut | Overall length |

PU

|

Please login to see the price |

|---|---|---|---|---|---|---|---|

|

21000073 / 4007220770191

|

TOUGH | 0.315 Inch | 0.236 Inch | 0.787 Inch | 2.362 Inch | 1 piece | Login / Register |

|

21000075 / 4007220770207

|

TOUGH | 0.394 Inch | 0.236 Inch | 0.787 Inch | 2.362 Inch | 1 piece | Login / Register |

|

21000076 / 4007220770214

|

TOUGH | 0.472 Inch | 0.236 Inch | 0.984 Inch | 2.559 Inch | 1 piece | Login / Register |

|

21000129 / 4007220090947

|

TOUGH | 0.472 Inch | 0.236 Inch | 0.984 Inch | 6.89 Inch | 1 piece | Login / Register |