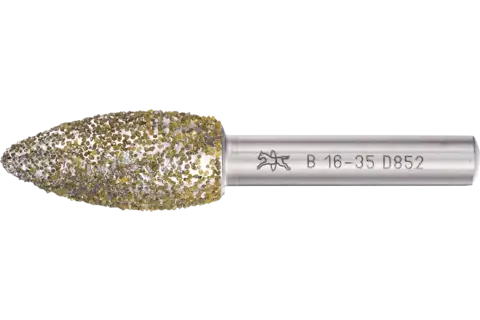

Technical information

- Dia. external

- 5/8 Inch

- Dia. external

- 16 mm

- Dia. shank

- 8

- Dia. shank

- 8 mm

- Grit size

- D 852

- Length, shank

- 1-9/16 Inch

- Length, shank

- 40

- Width

- 1-3/8 Inch

- Width

- 35 mm

- Packaging unit

- 1 piece

Description

Advantages

Recommendations for use

Ordering notes

- Materials that can be worked

- Applications

- Drive types

PFERDVALUE