Technical information

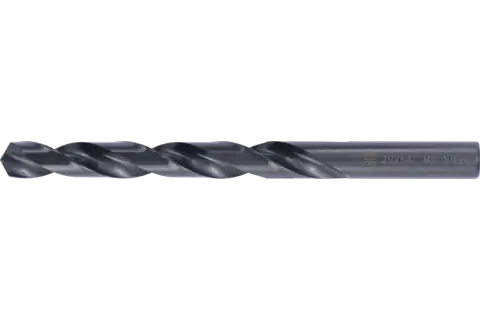

HSS Twist Drill 29/64" M2 STEEL

- Angle

- 118 °

- Diameter

- 29/64 Inch

- Diameter

- 11.51 mm

- EDP no.

- 20028

- Flute length

- 4-1/6 Inch

- Flute length

- 106 mm

- Overall length

- 5-5/8 Inch

- Overall length

- 143 mm

- RPM from, grey cast iron, white cast iron

- 280 RPM

- RPM from, hard non-ferrous metals

- 700 RPM

- RPM from, soft non-ferrous metals

- 840 RPM

- RPM from, steels over 220 HV (95 HB)

- 560 RPM

- RPM from, steels up to 220 HV (95 HB)

- 700 RPM

- RPM from, thermoplastics, fibre-reinforced plastics (GRP/CRP)

- 420 RPM

- RPM to, grey cast iron, white cast iron

- 700 RPM

- RPM to, hard non-ferrous metals

- 1390 RPM

- RPM to, soft non-ferrous metals

- 1670 RPM

- RPM to, steels over 220 HV (95 HB)

- 700 RPM

- RPM to, steels up to 220 HV (95 HB)

- 969 RPM

- RPM to, thermoplastics, fibre-reinforced plastics (GRP/CRP)

- 1110 RPM

- Spiral angle, from

- 25 °

- Spiral angle, to

- 30 °

- Version

- STEEL

- Packaging unit

- 5 pieces

Description

Advantages

Recommendations for use

Safety notes

- Materials that can be worked

- Applications

- Drive types