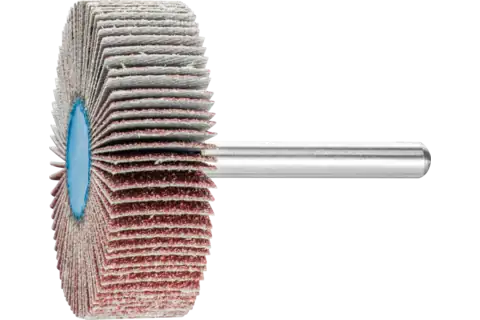

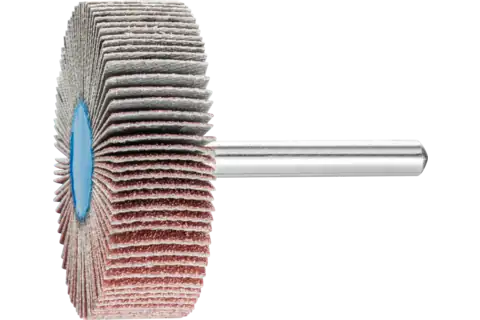

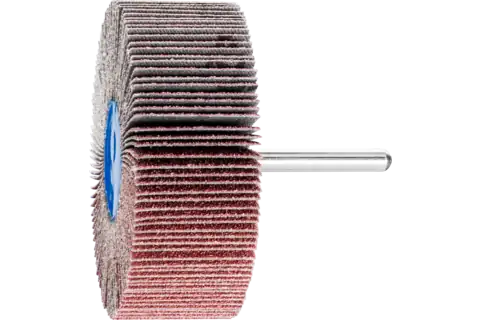

Mounted flap wheel set

mounted flap wheel set FSO 5400 dia. 40 to 80mm width 15 to 40mm grit 60 to 150

FSO 5400

Technical information

mounted flap wheel set FSO 5400 dia. 40 to 80mm width 15 to 40mm grit 60 to 150

- Height

- 9-1/2 Inch

- Height

- 240 mm

- Length

- 9-1/2 Inch

- Length

- 240 mm

- PFERD TOOLS type

- FSO 5400

- Width

- 5-3/4 Inch

- Width

- 145 mm

- Packaging unit

- 1 piece

Description

Special features

Recommendations for use

Safety notes

- Materials that can be worked

- Applications

- Drive types

PFERD TOOLS VALUE

PFERD TOOLS ERGONOMICS

recommends mounted flap wheels to reduce vibration and noise produced during use and to improve comfort when working.